How to create a new process

Last update: 21 December 2022

This howto describes how to create a new process. In this how-to we wil create the following process

SiN2 deposition on Chamber1 of OXFORD PECVD with the following parameters

| Parameter | Value | Unit |

|---|---|---|

| SiH4 flow | 100 | sccm |

| Ignition power | 1 | Watt |

| Power | low or high | |

| Thickness | 40 | nm |

Pre requirements

Before a new process can be created, first some basic information has to be collected. These are

- Module (component) of Equipment

- Set of parameters of Equipment module

- Name of process (family)

- Classification in process type and process category

Step 1: Select a module on an equipment

Each process is executed on a module of an equipment, for example on one of the process chambers of a deposition equipment. Smaller tools are not split in different modules and only have a main tool.

In this example we will use the OXFORD PECVD with 2 chambers

- Chamber 1

- Chamber 2

If necessary equipment has not been created yet, then equipment can be created via Equipment > Equipment and then

click the button “Create equipment”. There is a dedicated

howto how to create new equipment

Note that equipment has to have the option Can execute processes set to Can execute processes (issues and ECN notes are available) in order to be used in a process

Step 2: Check the parameters (and units) of the module

In SoloDB the default setting is that parameters of a process are defined by the equipment module. The idea behind this is that the equipment module is connected to several facilities and has other fixed properties like temperature control, pressure control or control for power.

In this (simplified) example we need to deposit a layer of SiN2 for which we need Silane gass and we need to ignite the plasma and determine a power during the deposition and finally a total thickness of the SiN2 layer.

This results in 4 parameters, which are:

- SiH4 flow

- Ignition power

- Power

- Thickness

The following units are needed for this example

- sccm

- Watt

- nm

The choice of parameters and units depends on personal preference, the more parameters are logged the more detail is available later but it is also possible to only log the most relevant parameters. SoloDB also allows to log all parameters but only show Emphasized parameters.

All parameters are available via Library > StepParameters and new parameters can be created using the button “Create

parameter”, units can be found via Library > Units. Before continuing make sure all parameters and units are

available. Note that parameters and units are shared between equipment modules so try to keep the names general.

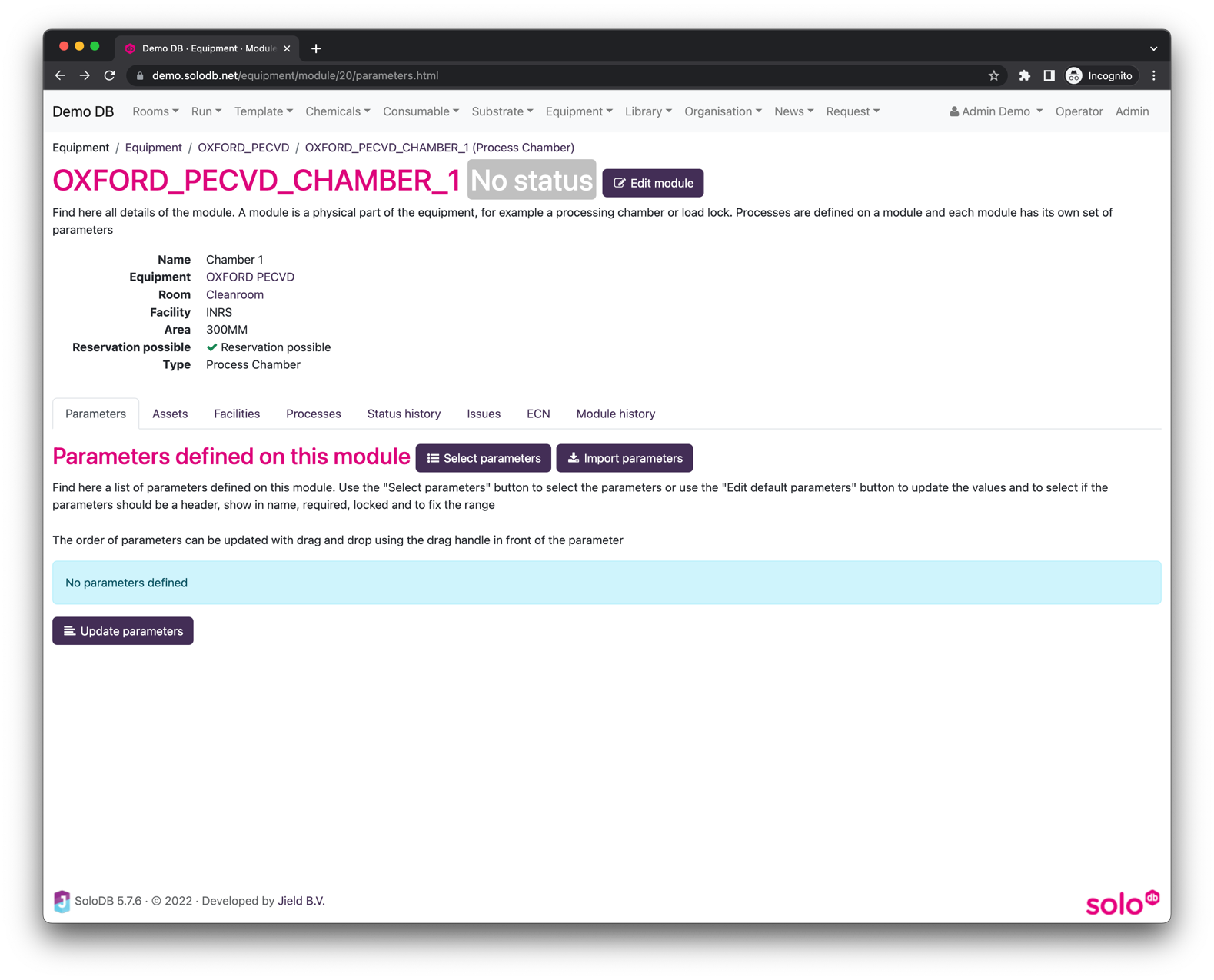

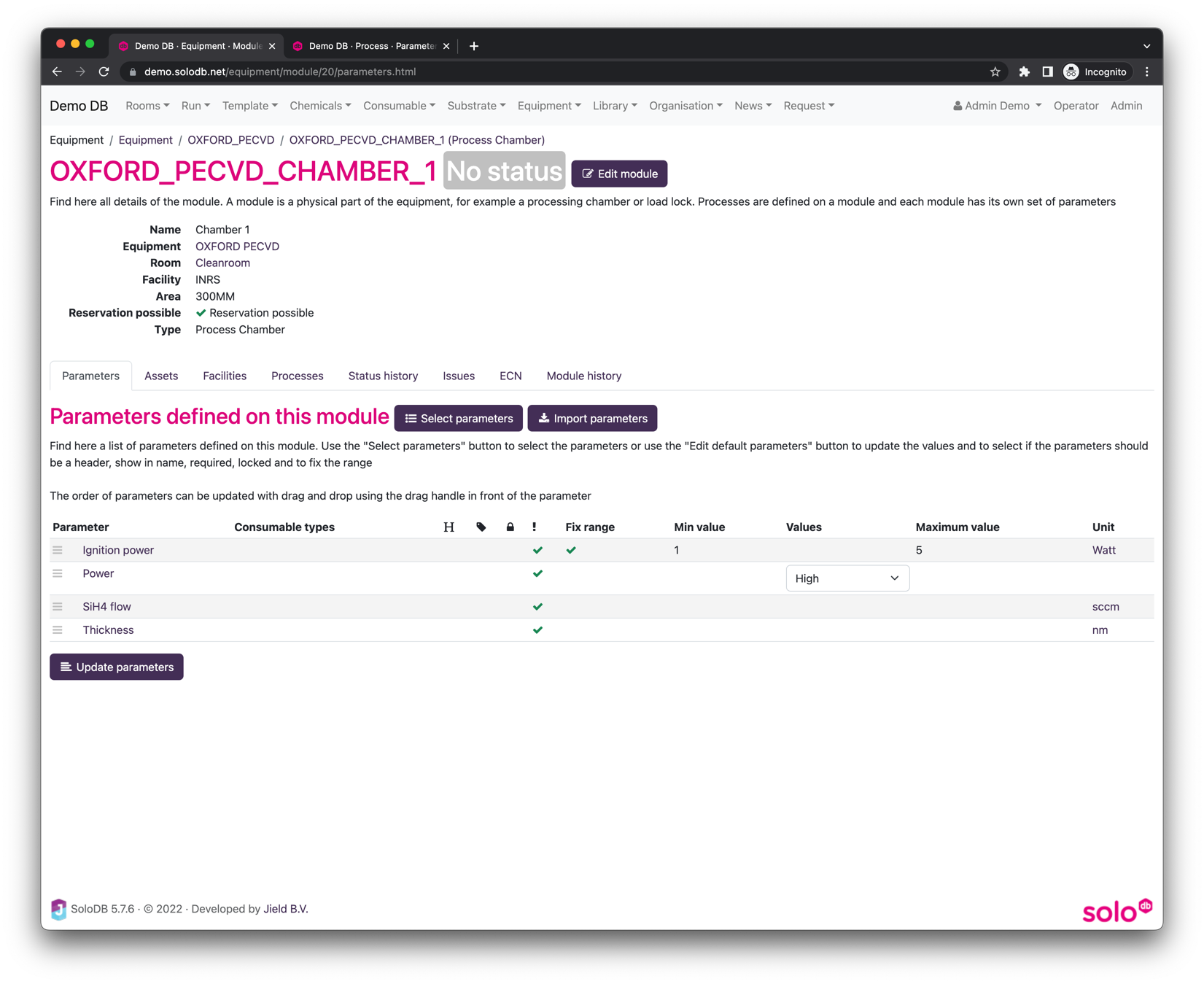

When the equipment module has been created, no parameters are defined for this module.

Use the button “Select parameters” to select the required parameters for the equipment module

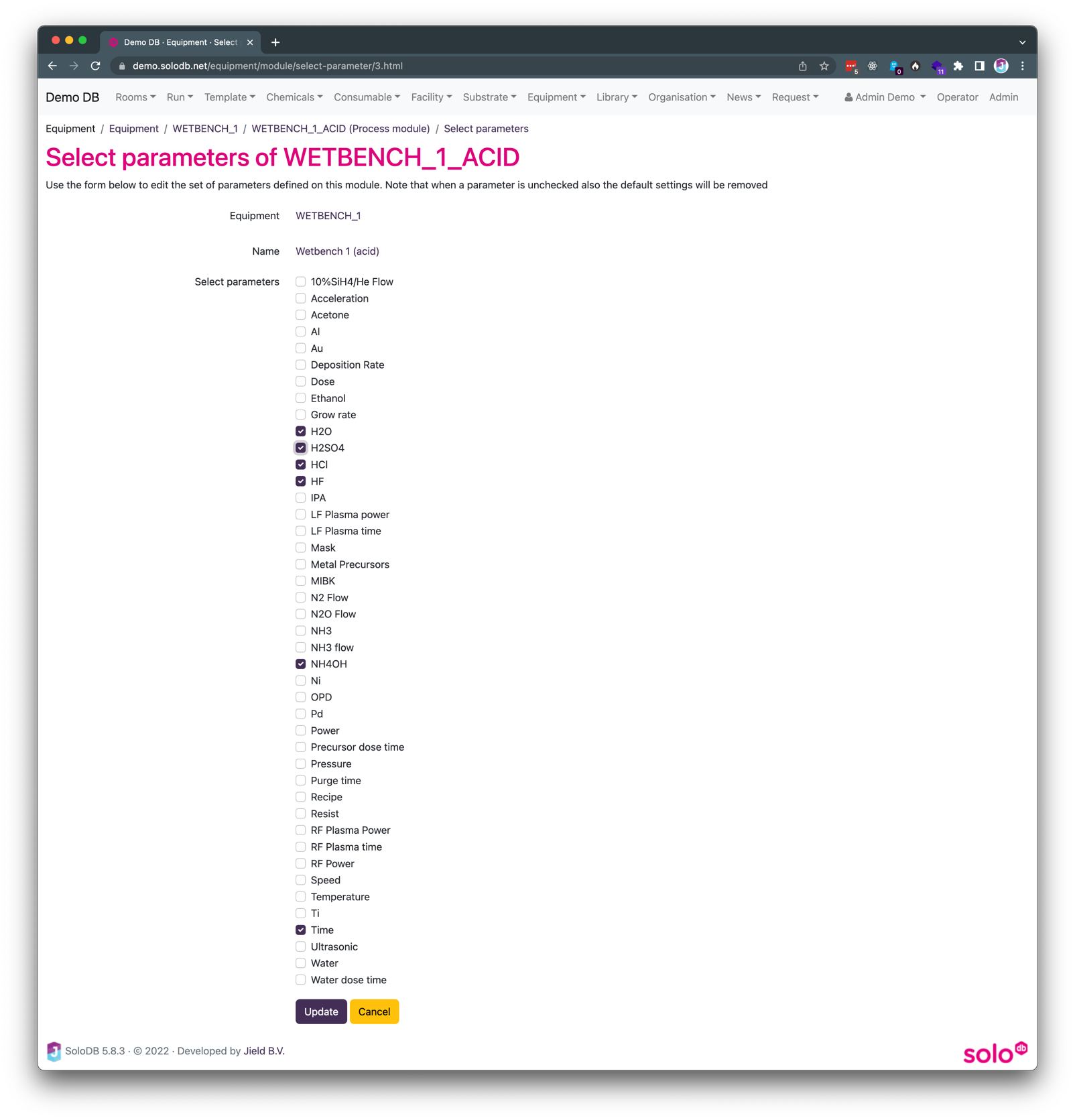

Check the checkbox in front of the required parameters and press “Update” below. After submission a new form is shown where the correct unit and other properties per parameter can be set.

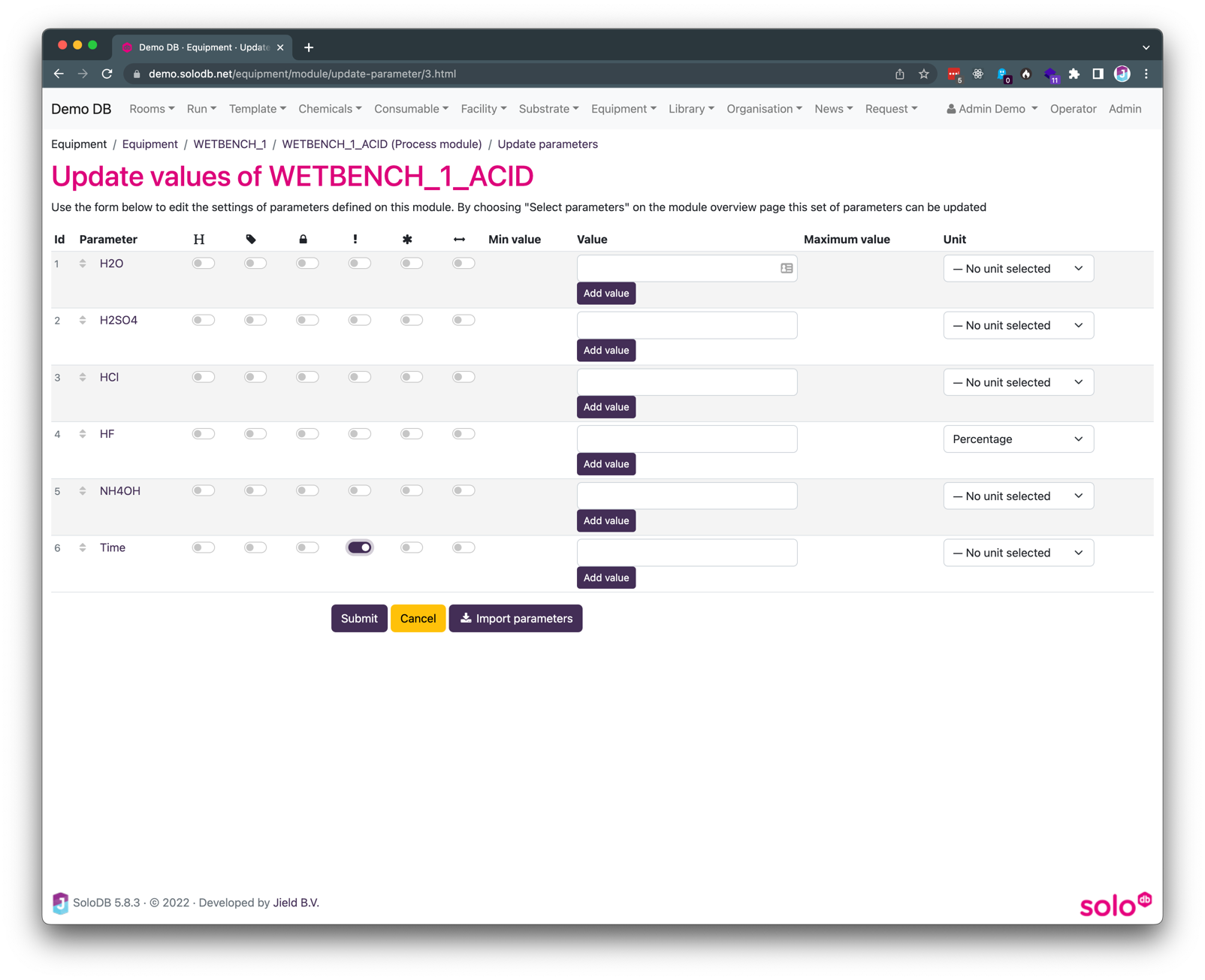

In this form the following options are possible

- Using the handle the order of the parameters can be changed

- If the checkbox in the H column is checked the parameter is ignored but the line is used as a header. This can be used to group several temperature parameters together

- If the checkbox in the label column is checked the value of this parameter is shown in the process name in the run step overview

- If the checkbox in the locked column is checked the value of this parameter cannot be changed

- If the checkbox in the Exclamation mark column a value for this parameter is required. Note that this setting cannot be combined with the H column

- If the checkbox in the min-max column is checked it is possible to set boundaries (min and/or max) for the provided values

- The Min/Max value columns are used in case the checkbox is set in the min-max column

- The asterisk column indicates the visibility of the parameter in the run step overview. If the asterisk is not visible the parameter default shown in the step overview unless “Show only emphasized parameters” is unchecked

- The value provided in the value column is a default value and can be overwritten in the run (not if the locked checkbox is checked). The multiple values are given here (in case of the ignition power) SoloDB will render a dropdown and the user has to choose one of the values from the dropdown

- In the unit column a unit can be chosen per parameters. The chosen unit need to match the units used on the equipment module

After submission the equipment module is ready to be used and process families can make use of the equipment module

Step 3: Create the process on the equipment module

In this HOWTO we create a process called SiN2 deposition, which is a deposition step. SoloDB allows a flexible categorisation of processes using three levels and for this howto the correct process family has to be selected or created in case it does not exist

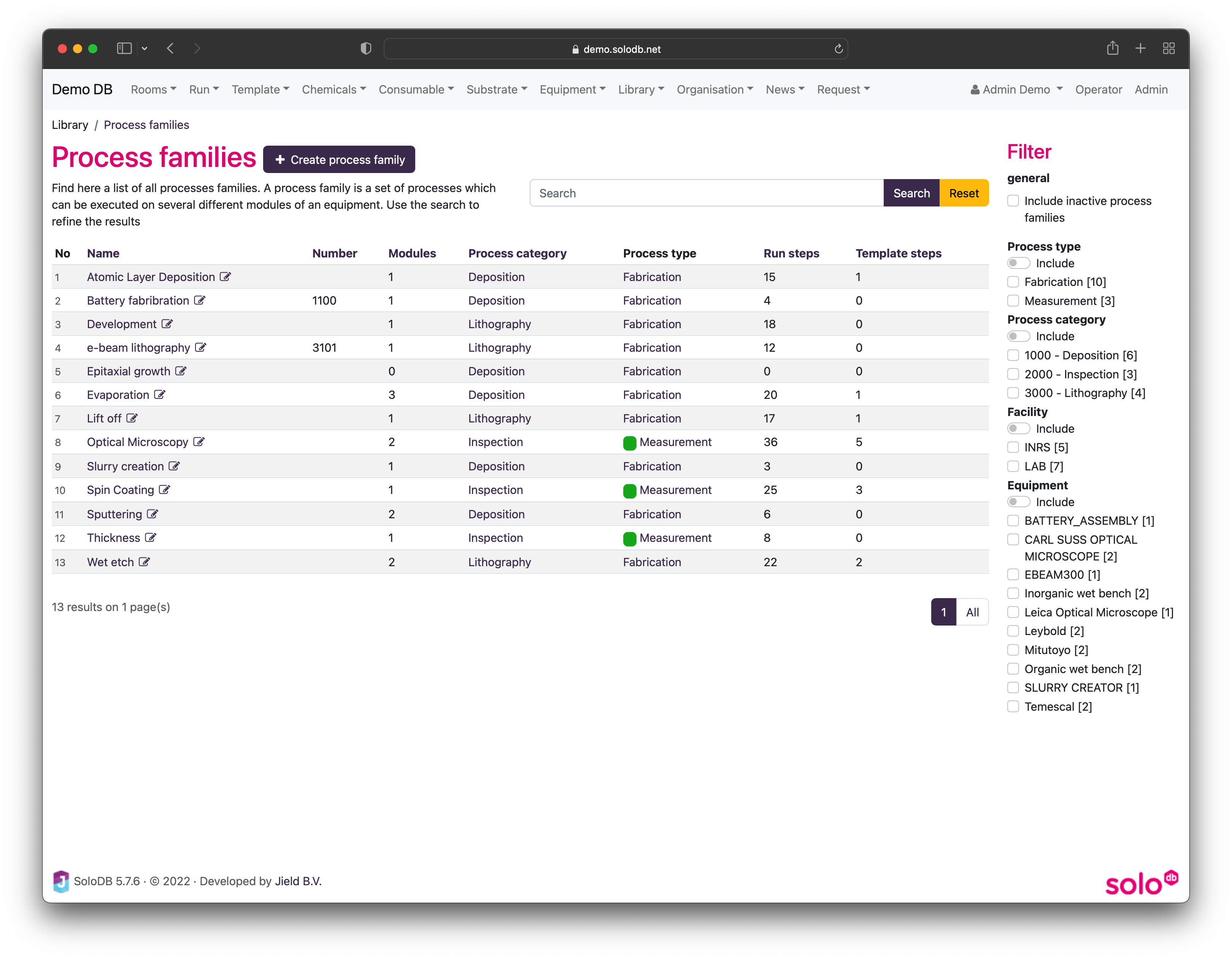

In this HOWTO we create a process which is a process family executed on a equipment module. Process families can be

found via Library > Process Families

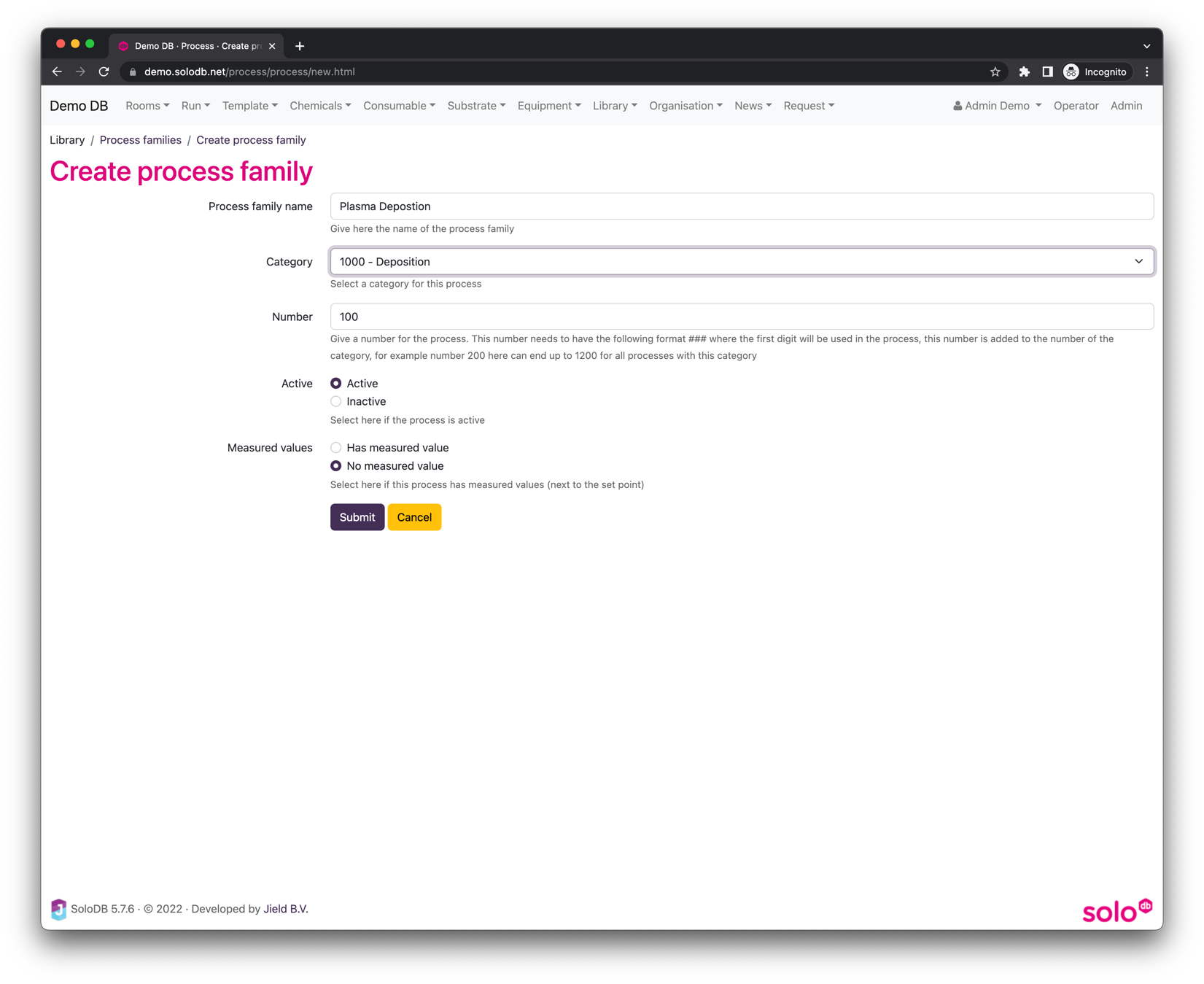

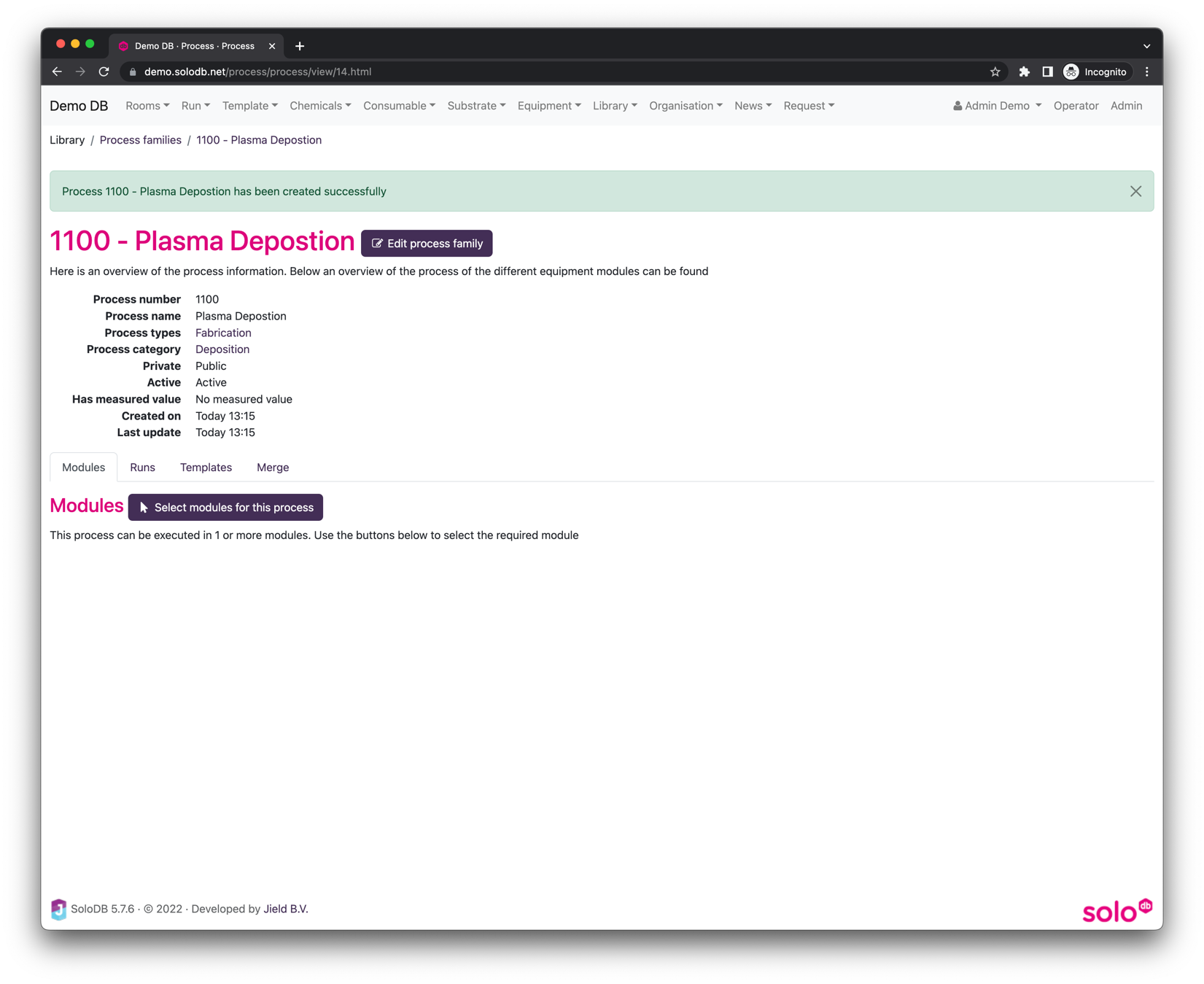

If the required process family cannot be found, use the button “Create process family” to create a new process family. In this HOWTO a new process family called Plasma deposition is created, this process family fits in the category Deposition

If the process family already exists then this can be selected, if the process family is opened, it will be possible to select an equipment module on which the process family can be executed (resulting in a process which can be used in runs)

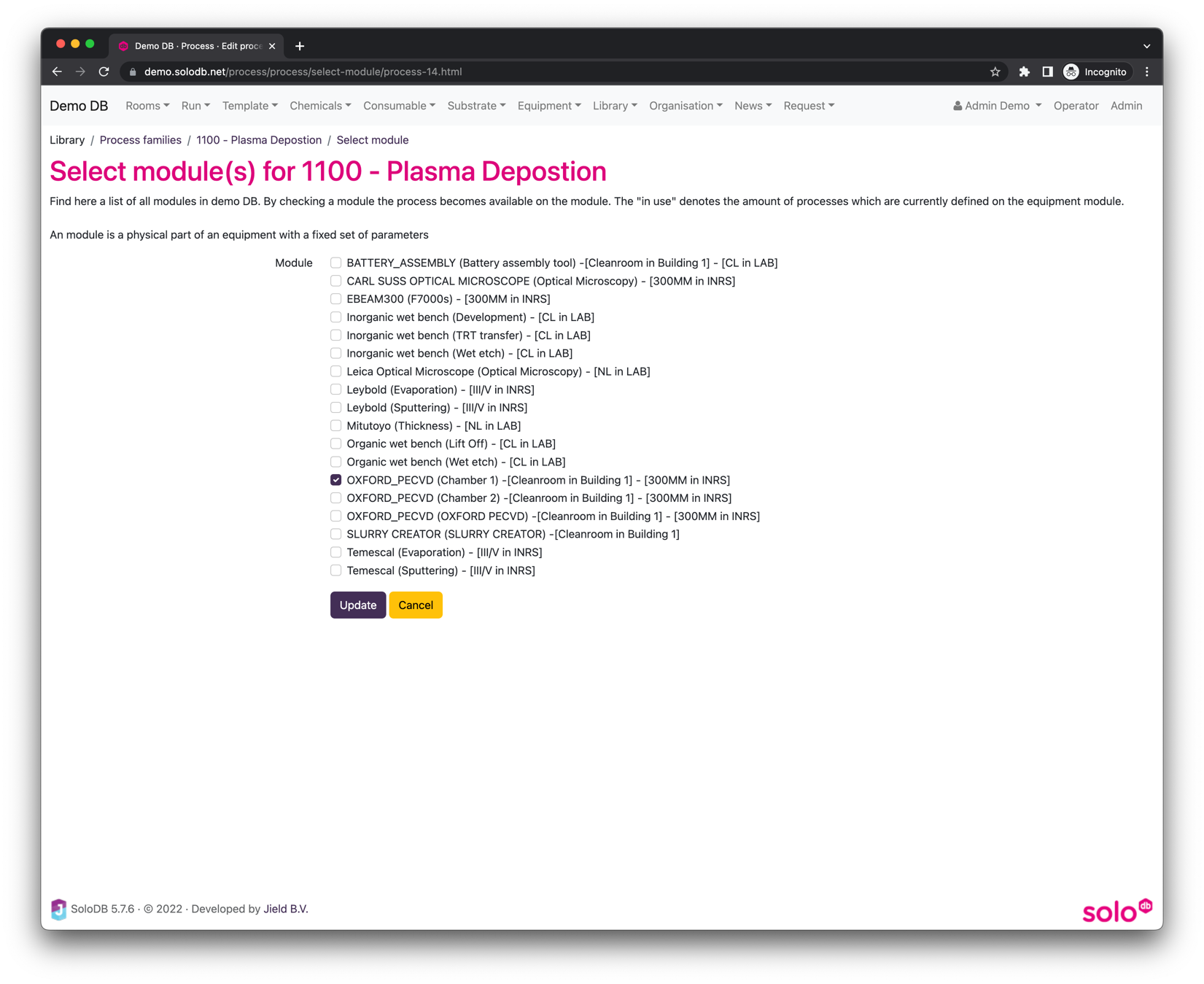

Use the button “Select modules for this process” and select the module on which this process family can be executed.

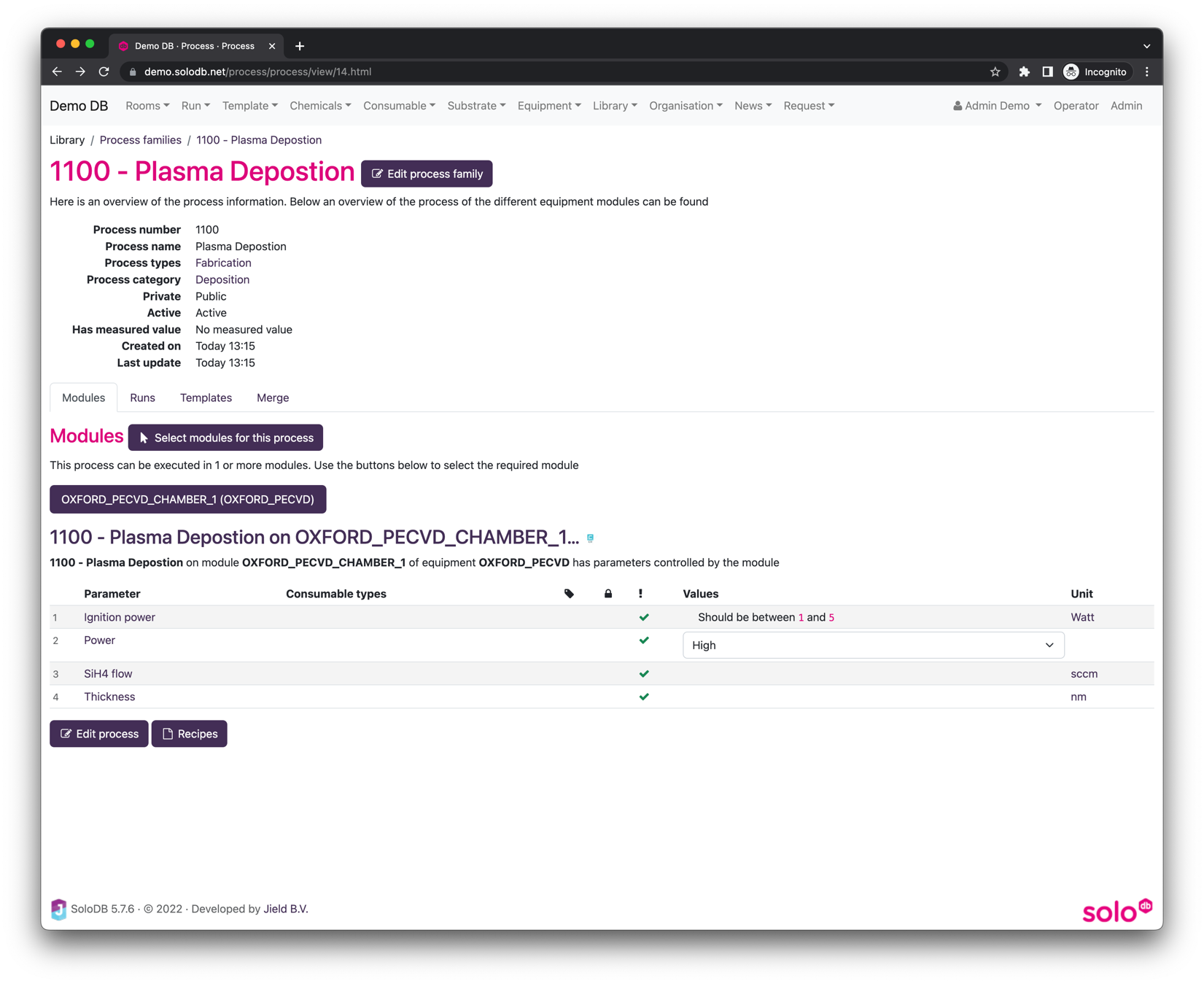

After submission the process is listed on the process family detail page under the tab “Modules”

The process is now ready to be used in runs, templates and monitored processes.